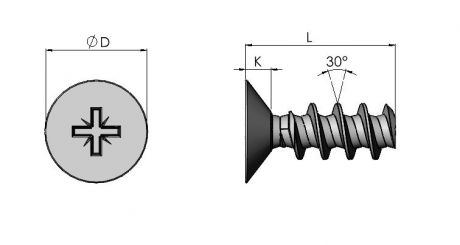

Polyplast 30 Pozi Countersunk Head

Series 20210 Type: 1413

The 30 deg. Flank angle produces low radial forces when engaging the plastic, therefore resulting in less radial stresses, in other words the hoop stresses in the plastic bosses are less than those experienced with conventional screws. The recessed core geometry provides the ideal flow director for the displaced plastic, encouraging a uniform flow to fill the pitch of the screw without material jamming. This results in the maximum amount of plastic being engaged providing higher sheer loads and pull out force.

Material: Steel, Stainless Steel A2 (Selected Sizes Only)

Finish: Zinc Plated, Self Colour

For the part number replace ** with the desired length found in the tables below:

Part Lengths

| Legend | |

| • | Usually Available from Stock |

| • | Special Order Only |

| • | Not Available |

Please refine your sample request by selecting a length from the following table; your selected sample has been highlighted:

| THREAD/LENGTH | 5 | 6 | 8 | 10 | 12 | 14 | 16 | 18 | 20 | 25 | 30 |

| 2.2 | • | • | • | • | • | • | • | • | • | • | • |

| 2.5 | • | • | • | • | • | • | • | • | • | • | • |

| 3 | • | • | • | • | • | • | • | • | • | • | • |

| 3.5 | • | • | • | • | • | • | • | • | • | • | • |

| 4 | • | • | • | • | • | • | • | • | • | • | • |

| 5 | • | • | • | • | • | • | • | • | • | • | • |

| 6 | • | • | • | • | • | • | • | • | • | • | • |